本サイトはスタイルシートを使用しております。

お客様がご使用のブラウザはスタイルシート非対応のため、表示結果が異なっておりますが、情報は問題なくご利用いただけます。

|

|||||||

|

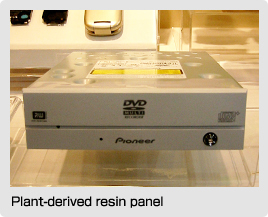

One of Pioneer’s persistent, but inconspicuous, pursuits in developing characteristic products is adopting eco-friendly materials while offering designs vouched for by advanced functions, high performance and reliability, as well as quietness. Specifically, as our industry leading efforts to abandon the reliance on petroleum products, we have been expanding our use of plant-based resins ever since we became the first in the world to commercialize drives that use such plastics. A drive is comprised of many different plastic parts---a front panel, a bezel, buttons, and a tray---to name a few. Before the introduction of non-petrochemical plastics, we had been working on designs that enabled easy recycling, drawing on our internal environmental standards, in addition to affixing labels that identified the materials used, which was the industry-wide norm. However, we naturally came to think that, that’s not Pioneer doing, and got our feet wet with the new challenge. So, in joint effort with resin material manufacturers, we set out in pursuit of the best drive---a non-petrochemical product---using plant-derived resin. While we secretly got on with investigating and discussing the adoption of plant-derived resin for outer parts of the drive, we also cooperated with the marketing members from early on in the process and studied the effective applications of plant-based resins, the societal problems surrounding plant-based resins, as well as how to turn them into a business product. |

|||||||

|

|||||||

Petrochemical resin is a mature technology, with all kinds of resin able to accommodate any purpose or performance requirement. On the other hand, plant-based resin is still a developing technology. Loosely speaking, it does not share most of the applications covered by petrochemical resin. Then there are also the problems of production yield, challenges of production processes, labeling with respect to environmental impact, and so on. People also tend to confuse biodegradable plastic with plant-derived resin, so we were quite careful when we gave explanations to our clients. The actual development took a two-pronged approach: We supported the development of the materials, and the establishment of technologies to utilize plant-based resin in our products. We created test pieces one by one with the resin manufacturer staff, evaluated them and improved on them. It was an oft-repeated, low-key task. * For information on carbon neutrality, click on the link below. http://pioneer.jp/environment/ecoproducts/prevention.html#3 |

|||||||

|

|||||||

|

|||||||

|

|||||||

Our exclusive “PureRead” function is also equipped on most of our models, including DVR-XD09, to conduce to reducing waste by being able to read audio data from old or damaged CDs that would otherwise have been thrown away. |

|||||||

|

|||||||

|

|||||||